The CUP Series Ethanol Alcohol Extraction System - Patented, Certified UL 1389, ISO 9001, PSI Reviewed

The NEW 2020 CUP Series alcohol extraction system is now fully patented (Patent #10814338), UL/CUL 1389, PSI reviewed, and ISO 9001 certified. This makes the CUP Series the first US-manufactured extraction equipment to adhere to these respected industry-wide standards.

What do these certifications mean to you–our customer?

They reduce business risk by expediting approval by your local AHJ (Authority Having Jurisdiction) to help get your lab up and running fast. But more importantly, certifications and industry standards also ensure the safety of your facility and staff.

About the CUP Series Ethanol Extraction System

The CUP Series (CUP-5, CUP-15 and CUP-30) delivers the ability to extract and target compounds from a variety plant materials. The Centrifuge Utility Platform (CUP) combines closed-loop, alcohol extraction with mechanical centrifugation ensuring a high-purity, consistent extraction. This extraction technology can target specific plant compounds through programmable sequences, effectively isolating the desired separation.

Boasting a 97% alcohol removal from biomass, the CUP systems streamline production times and maximize extraction yield. Designed and built in northern California, Delta Separations is taking US craftsmanship to the next level.

97%

Alcohol Removal

98%*

Botanical Compound Removal

*Results can vary depending upon biologicalmakeup of source material

1

Single Operator

CUP Series Technical Details

Standard on all CUP systems

- Closed-Loop system

- Designed for single operator

- Easy material loading / unloading

- Controlled alcohol residence time

- All wetted parts are 304 and 316L sanitary stainless steel

- Vacuum jacketed insulation

- Alcohol feed port with 1.5” tri-clamp fittings

- Vapor tight (no pressure) vessel with EPDM lid seal

- 2” Tri-Clamp Angled Drain

- Low temperature rating to -40c

- 3rd Party Engineer Reviewed by PSI

- UL certified electronics [C1D2] U.S. / Canada

CUP-5

Production Capacity

- 3.5 pounds* (1.6 kilograms) of Plant Material Per Batch

*Depending on mill size - Avg. Run Time: 2-12 Min*

*Depending on SOP - Approx: 150 pounds (136 kilograms) Processing Per 8 hr Shift

- Alcohol Requirement: 5 gallons (18.9 liters) per run

CUP-15

Production Capacity

- 8-14 pounds* (3.6-6 kilograms) of Plant Material Per Batch

*Depending on mill size - Avg. Run Time: 10 – 20 Min*

*Depending on SOP - Approx: 300 pounds (136 kilograms) Processing Per 8 hr Shift

- Alcohol Requirement: 12-13 gallons (45-49 liters) per run

CUP-30

Production Capacity

- 25-30 pounds* (11-13.6 kilograms) of Plant Material Per Batch*Depending on mill size

- Avg. Run Time: 10 – 20 Min*

*Depending on SOP - Approx: 600 pounds (272 kilograms) Processing Per 8 hr Shift

- Alcohol Requirement: 25-30 gallons (95-113.5 liters) per run

Recommended Ancillaries

View our recommended ancillaries list by using the direct link below.

Download System Pricing

Speed of Processing

Runtime for CUP-5 is 12 minutes, CUP-15 is 15 minutes and CUP-30 is 20 minutes, allowing operators to process up to 600 pounds of material in a standard eight-hour shift. With the touch of a button, the automated program menu runs the cycle to the user’s specifications. Compare the CUP Series.

Ease of Operation

Ever run a washing machine to do your laundry? Congratulations! You are on your way to becoming an operator of the CUP Series extractors. It’s as easy as 1-2-3.

- STEP 1

- STEP 2

- STEP 3

Operator packs a mesh bag with biomass, places the bag in the vessel and locks the lid.

The unit is filled with ethanol alcohol from the source tank initiating an agitated wash and spin cycle, extracting the plant material and removing any remaining alcohol mixture.

The system then drains, and the alcohol tincture is ready for further processing.

Operator packs a mesh bag with biomass, places the bag in the vessel and locks the lid.

The unit is filled with ethanol alcohol from the source tank initiating an agitated wash and spin cycle, extracting the plant material and removing any remaining alcohol mixture.

The system then drains, and the alcohol tincture is ready for further processing.

The CUP Series Provides Accurate Control over Critical Extraction Variables

- Basket RPM

- Controlled alcohol residence time

- Controlled basket RPM speed

- Cycle Agitation Strength

- Spray Wash Stripping

- Plant Material Drying

- Temperatures

- Ethernet Connection (IoT compatibility)

- Data Logging

- Manual and Automatic Cycle Programming

- Min/Max Parameters

- System Troubleshooting

- Cycle Tracking

- Administrative Functions

About our Certifications

The CUP Series (Patent Pending) is the first US-manufactured patent pending botanical extraction equipment to be UL/CUL 1389, PSI reviewed, and ISO 9001 certified–respected industry-wide standards.

Meeting these high standards of quality ensures that not only are you buying the best-in-breed US-manufactured alcohol extraction equipment but you’re also reducing business risk by making it easier and faster for your AHJ (Authority Having Jurisdiction) to approve your extraction lab.

Our goal has always been to help you build your business and support your success.

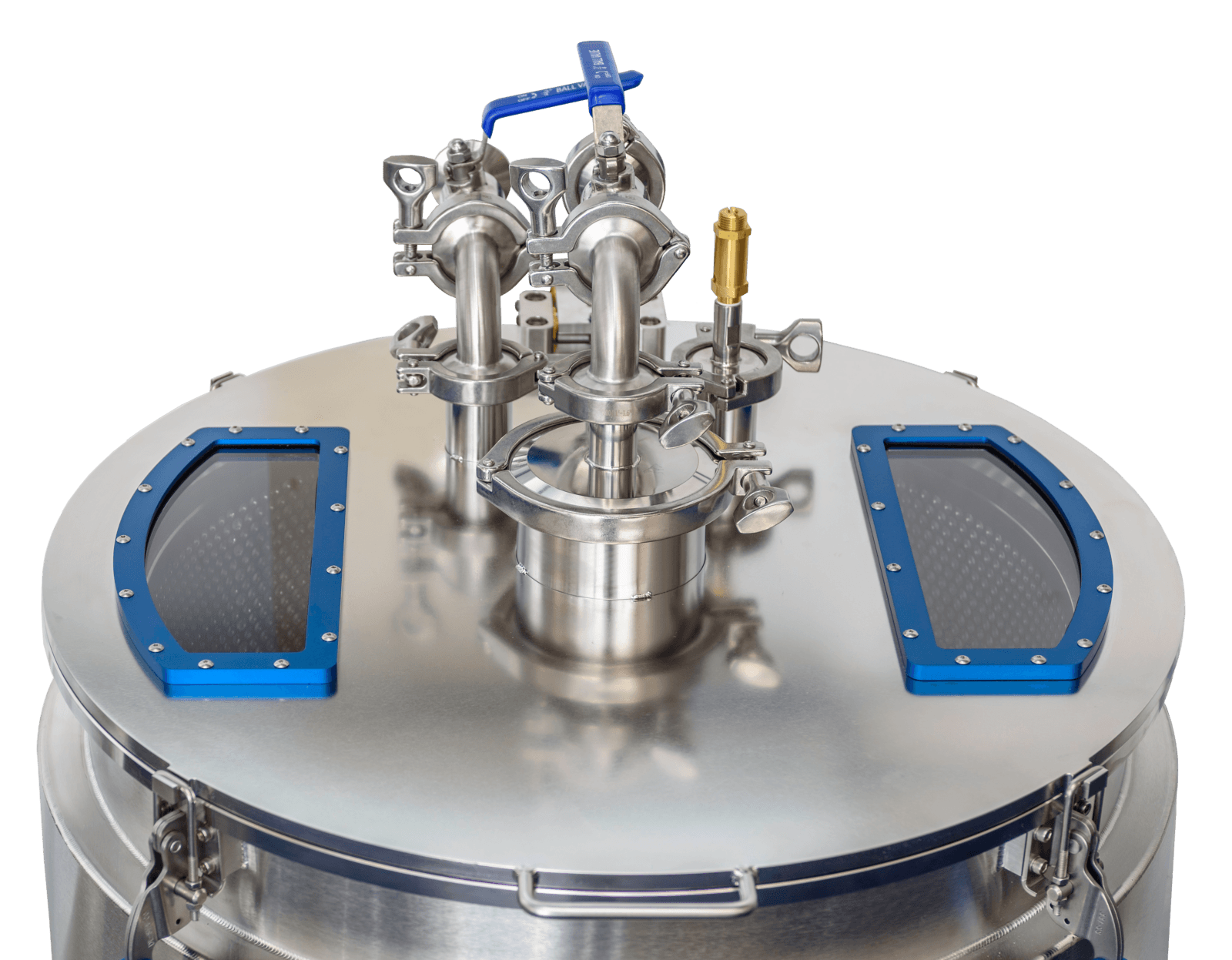

State of the Art Craftsmanship

We celebrate our craft with passion and attention to every meticulous detail. This ensures a product that is guaranteed to perform to the industry’s highest standard.

In full compliance with closed-loop system certifications, our stainless-steel CUP machines are thoughtfully engineered for safe and reliable performance.

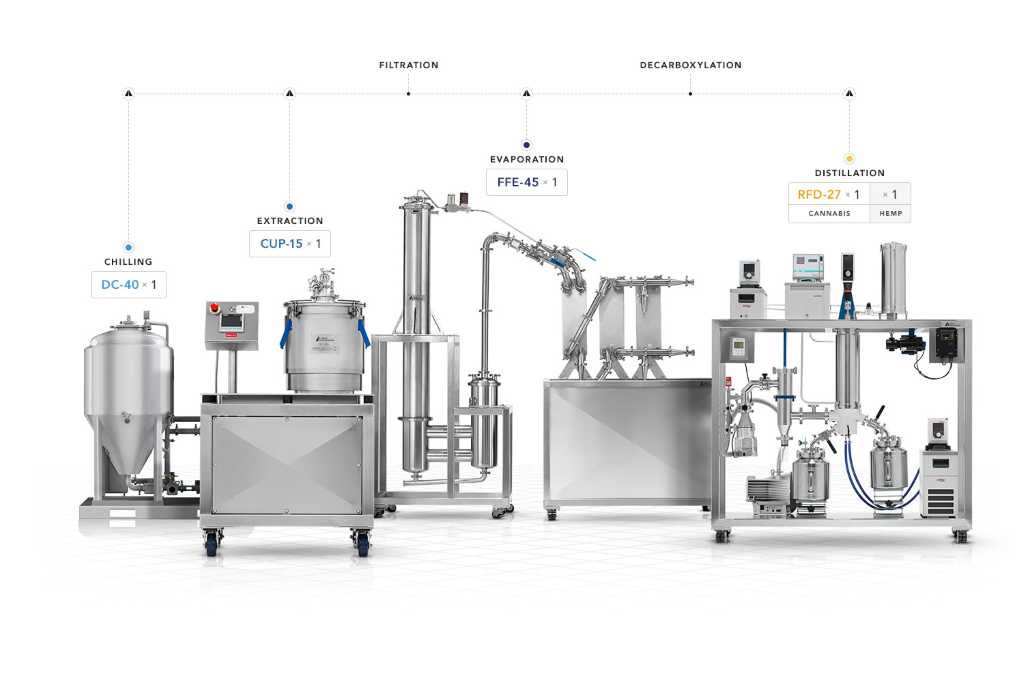

What Other Equipment will you need for your Ethanol Extraction Lab?

Learn more about Ethanol Extraction

All plants, such as cannabis, produce an essential oil. In order to access this oil, usually a solvent is utilized to separate the oil from the plant matter. Ethanol alcohol allows extractors to concentrate the plant oil into a more refined end-product, which can then be used by itself or infused into foods or topicals.

Ethanol AKA alcohol (a colorless volatile flammable liquid) is an ideal solvent for the extraction processes because it’s a polar solvent that easily mixes with water and dissolves water soluble molecules such as chlorophyll, but also has the ability to dissolve many other, non-polar compounds, such as cannabinoids. Ethanol is also readily available and cost effective. Using the proper ethanol extraction equipment, thousands of pounds of cannabis and other plant products per day can be efficiently extracted.

Ethanol extraction is a process that can be done under either warm, cold, or room temperature conditions depending on your desired end-product.

For warm or room temperature ethanol extraction, the ethanol is used to quickly wash the plant material which gives a full spectrum concentrate.

For cold ethanol extraction, an industrial extraction chiller can be used to provide chilled ethanol to perform the extraction. Cold ethanol extraction is best suited for producing concentrated cannabinoid distillates and isolates because it does not extract water soluble compounds like chlorophyll as easily.

Is Ethanol Safe for CBD Extraction?

Ethanol itself can be a dangerous chemical due to its highly flammable properties. However, using ethanol to extract CBD from hemp is a safe process if high-quality extraction equipment is used. Premium extraction equipment evaporates out all the ethanol, leaving negligible amounts behind in the product. In addition, new solvent recovery processes allow up to 98% of the ethanol to be recovered and re-used for future extractions.

While ethanol extraction does have its risks, when compared to other extraction methods ethanol is arguably the safer process. Hydrocarbon extraction (using butane or propane as a solvent to extract the plant materials and then heating the mixture to evaporate the solvent, leaving behind an extract), and CO2 extraction (subjecting carbon dioxide to high pressures until it becomes a fluid, extracting the plant material with this fluid, and then returning the CO2 to a gas phase to separate the extract) carry more risks and take longer to learn.

Learn more about other equipment that you may need for your ethanol extraction lab.