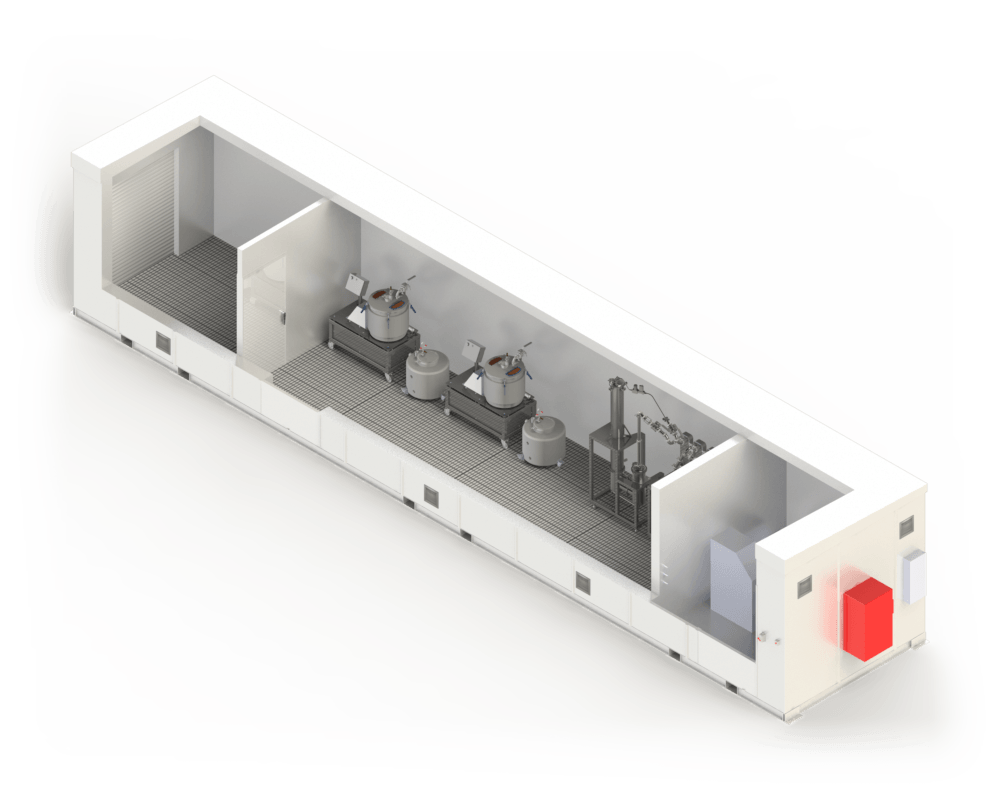

Modular Processing Lab

Designed with a focus on safety, compliance, and maximizing production efficiencies, the PRO-POD Max reduces business risk and time-to-permit by delivering a fully functional C1D2 certified extraction lab environment in the shortest time possible. Including a full suite of ethanol extraction and processing equipment, the PRO-POD Max is the fastest set-up, reliable, and compliant option to get your lab up and running fast.

Agile, moveable, and pre-designed to attach to on-site plumbing and electrical systems the PRO-POD modular lab space will accommodate a variety of configurations depending on your desired end-product outputs. Set up of your PRO-POD processing lab takes as little as 10-12 weeks. Save time and money by bypassing many of the typical permitting hassles by choosing the PRO-POD Max for your next extraction and processing venture.

The PRO-POD Max includes these Key Features:

- 4-hour Fire Rated Steel

- FM Global Approved

- Secondary Containment

- Dry Chemical Fire Suppression System

- Explosion Proof

- Optional rooms for Utility and Solvent Storage

Previous

Next

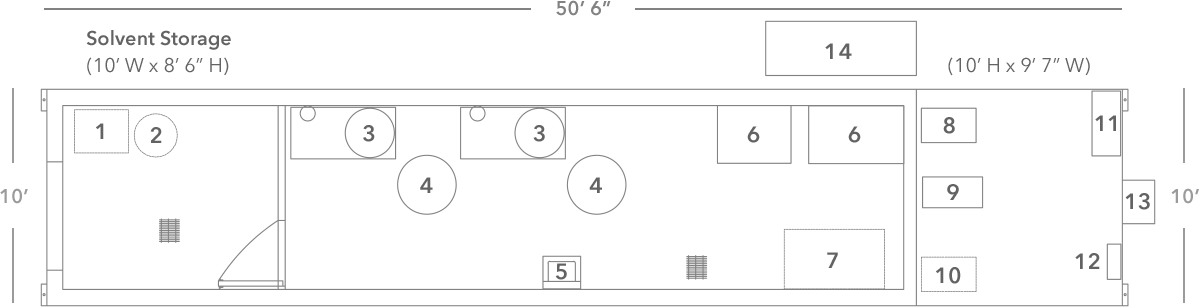

- 50' 6" L x 10' W x 10' H

Standard Package

- • C1D2 Certified/FM Global/NFPA

- • Four Hour Fire Rated Insulated Non-Combustible Steel Storage Building

- • Epoxy Coated Secondary Containment with Removable Galvanized Supports & Galvanized Grating

- • Heavy Gauge Steel Walls with Tube Frame & 10 Gauge Floor

- • Forklift Pockets

- • Seismic Tie Down Pads

- • Interior Ceiling Height 8’6” (Approx.)

- • Two Part Chemical Resistant Paint Interior & Exterior

- • Interior Ground Lugs with Exterior Ground Connection, Rod and Wire

- • DOT Placard & NFPA Rating Sign

- • NEMA 3R 400 Amp Load Center (1 Phase or 3 Phase)

- • Dry Chemical Fire Suppression System tied into Alarm Bell

Ethanol Storage

- • Four Hour Fire Rated Insulated Non-Combustible Steel Storage Building

- • Epoxy Coated Secondary Containment with Removable Galvanized Supports & Galvanized Grating

- • Heavy Gauge Steel Walls with Tube Frame & 10 Gauge Floor

- • Forklift Pockets

- • Seismic Tie Down Pads

- • Interior Ceiling Height 8’6” (Approx.)

- • Two Part Chemical Resistant Paint Interior & Exterior

- • Interior Ground Lugs with Exterior Ground Connection, Rod and Wire

- • DOT Placard & NFPA Rating Sign

- • NEMA 3R 100 Amp Load Center 1 Phase

Utility Room

- • Double Wall Insulated Non-Combustible Steel Storage Building

- • Plywood Subfloor with VCT Flooring

- • Heavy Gauge Steel Walls with Tube Frame and 10 Gauge Floor

- • Forklift Pockets

- • Seismic Tie Down Pads

- • Interior Ceiling Height 8’6” (Approx.)

- • Two Part Chemical Resistant Paint Interior & Exterior

- • 3 Each 120V 20 Amp Receptacles

- • DOT Placard & NFPA Rating Sign

- • NEMA 3R 100 Amp Load Center 1 Phase

- • 4’ LED Light Fixture with Exterior Switch

Recommended Lab Layout

- *Alcohol Chiller

- *Winterization Vessel

- CUP-30

- Discharge Tank

- Eye Wash Station

- FFE Pump & Cart

- *Rotary Evaporator

- Pump Chiller

- Recirculating Heater

- *Rotary Evap Chiller

- FFE Main Panel

- 2 CUP-30 Panels

- Dry Chem

- *Evap Chiller

* Non Delta Separations Supplied Equipment

Download Pricing

Highlights

Fast Permitting

Fully code compliant prefabricated structure with a complete set of state approved/sealed drawings ensuring an expedited permitting process and ease of approval.

Safety

Engineered to comply with all safety requirements for a C1D2 environment, including fire suppression, secondary containment, 4-hour fire rating and many more features.