Cold Ethanol Extraction: How it Works

Cold Ethanol Extraction: How it Works What is Cold Ethanol […]

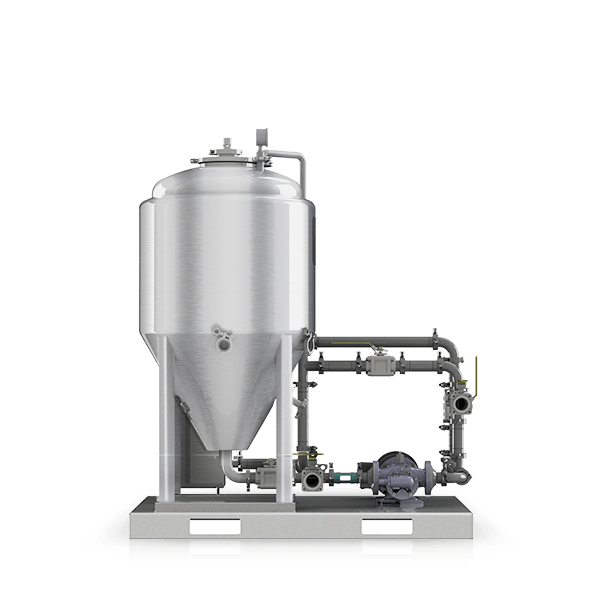

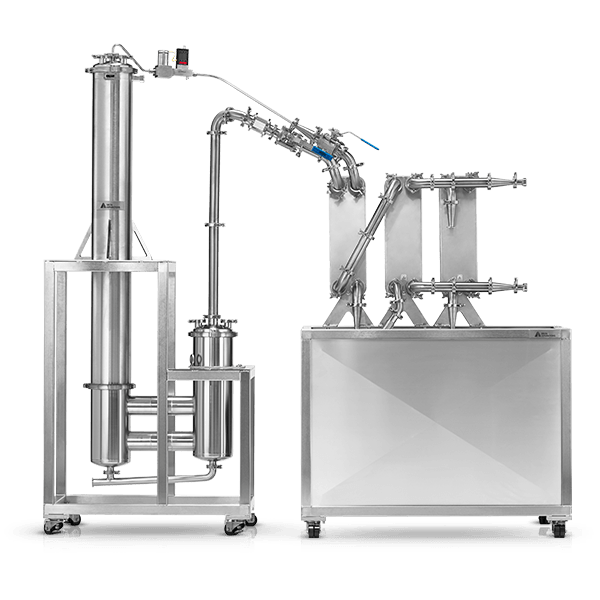

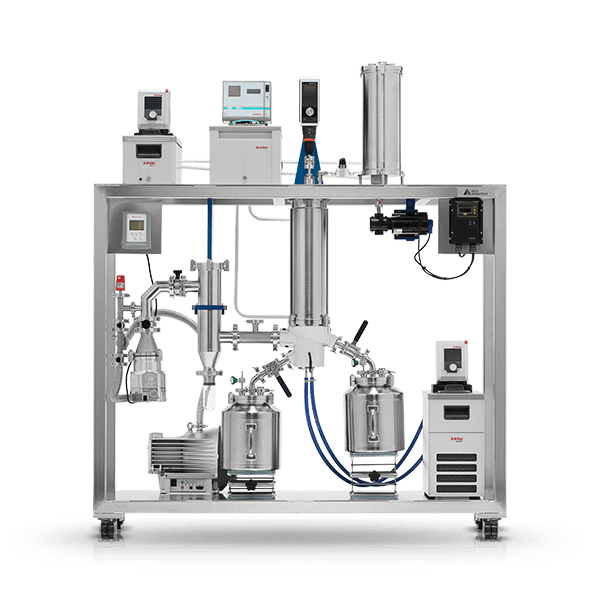

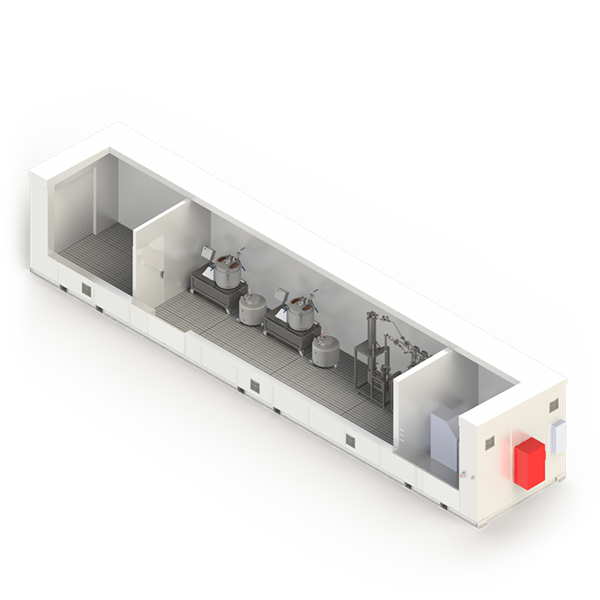

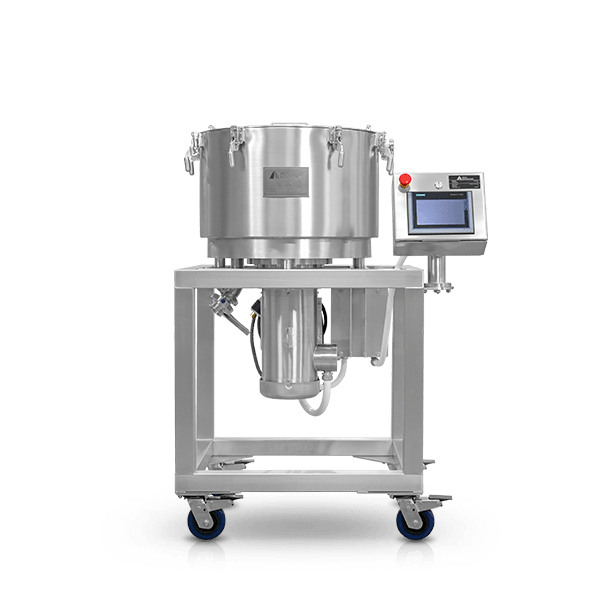

Ethanol extraction is one of the safest methods for extracting hemp/plant materials as well as the most scalable for your business. It only requires a C1D2 operating space and can be recovered for multiple cycles of extraction making your facility build more cost effective.

Water separation preserves the integrity of your plant material with the high grade solventless sieving process and creates a higher quality final product. Water separation is safe with low build out costs and easier permitting requirements.

"Delta makes the finest centrifuge equipment in the industry. It's engineered extremely well, allowing us to vary our SOPs to get exactly the targeted amounts of cannabinoids we want out of the process."

Cold Ethanol Extraction: How it Works What is Cold Ethanol […]

How to Ensure your Cannabis or Hemp Extraction Business Survives […]

CBN Oil Extraction — A Complete Guide to Extracting Cannabinol […]

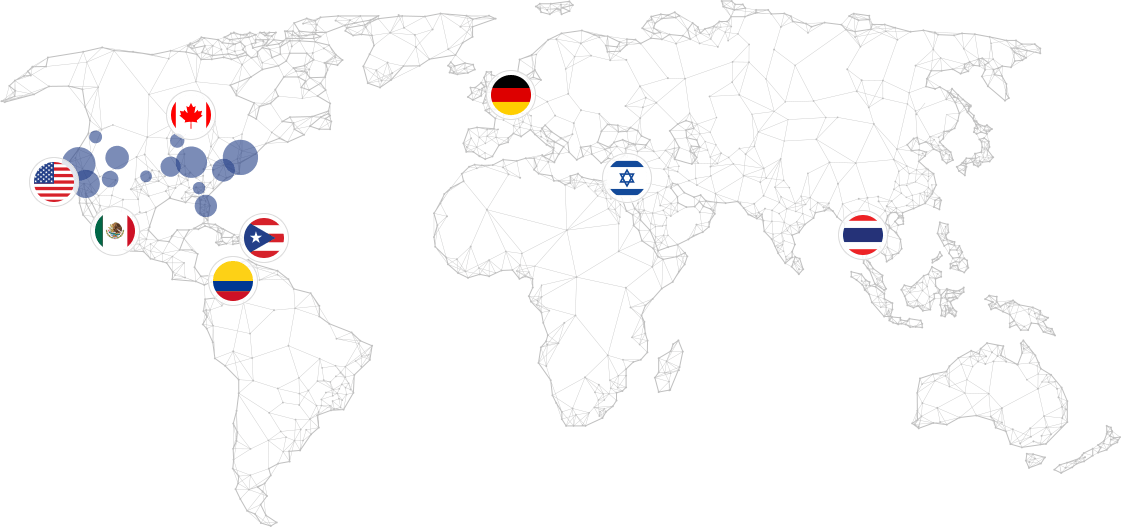

Delta Separations has over 700 systems in the field globally.

Address

Delta Separations

525 Portal St.

Cotati,

CA

94931

(707) 222-6066

sales@deltasepaprod.wpengine.com

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.

Prospiant is currently liquidating all in-stock extraction equipment and parts, providing you with the perfect opportunity to stock up on top-quality supplies at unbeatable prices.

To take advantage of these incredible deals while inventory is still available, reach out to ProcessingSales@prospiant.com. We appreciate your ongoing support.